Data center Infrastructure Service

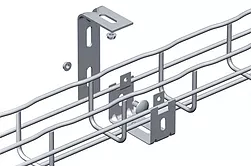

STEEL WIRE CABLE BASKET TRAY

KEPBER - FASTMAX series HDG/EZ/PG/PC/EZ+

Available in electro-zinc, pre-galvanised, powder-coated, hot-dipped galvanised, and electro-zinc plus finishes. KEPBER Steel Wire Cable Tray is offered in three standard depths – 30mm, 55mm and 106mm*, complemented by a wide range of available fittings to join and support the wire tray. In comparison to conventional tray, KEPBER Steel Wire Cable Tray is light in weight, enabling bends to be easily fabricated on-site. The design makes installation quick and convenient, thereby reducing on-site costs.Hot-dip galvanised (HD series)

KEPBER Hot-Dip Galvanised (HDG) finish is recommended for exterior use and more aggressive atmospheres. KEPBER HDG tray is coated to a thickness of between 60-100 microns. White rust may appear on the surface of the tray wires without affecting its resistance to corrosion, this is due to the formation of zinc hydroxycarbonate.

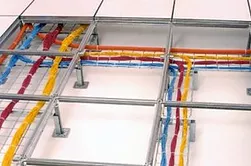

Electro-zinc (EZ series)

Electroplated Steel Wire Cable Tray is the standard and most popular range in Data center market place. With the current trend to ‘show off’ an installation,KEPBER Electro-Zinc trays are bright and shiny, giving a pleasing aesthetic finish. Adequate corrosion resistance and protection for most dry, internal environments, EZ Steel Wire Cable Tray can be used in both new and refurbishment projects.

Pre-galvanised (PG series)

Whilst Pre-Galvanising (PG) is also a method of hot-dip galvanising (HDG), it differs in the thickness of coating and the order in which the raw steel is treated – PG is treated prior to fabrication, rather than after. During manufacture, the wire enters an ammonium chloride (flux) mixture bath and then into a molten zinc bath. This will produce an average coating thickness of 20 microns (135 g/m2), offering protection against corrosion on cut surfaces due to the cathodic effect between zinc and steel. After the zinc coating is made smooth, it is then re-coiled. The finish is much smoother compared to that of a HDG finish.

Powder-coated (PC series)

KEPBER Powder-Coated Steel Wire Cable Tray is recommended for interior use in a range of atmospheric environments and is capable of withstanding a variety of corrosive conditions. The product is proving ideal for installers looking for extra protection above that offered by a hot-dip galvanized finish. Powder-Coated Steel Wire Cable Tray can also be used in exterior applications when the tray has also gone though a galvanizing process.

Electro-zinc plus ((EZ+ series)

In applications where additional corrosion resistance and protection is needed for a relatively short period of time, KEPBER can supply its increasingly popular Electro-Zinc plus range of Steel Wire Cable Trays.